In any electrocoating process, consistency is key. But temperature and humidity fluctuations can throw your e-coat line completely off balance. Seasonal changes, unexpected weather patterns, and uncontrolled indoor climates often lead to poor adhesion, coating defects, and increased downtime. Imagine the frustration when hard-earned production schedules get derailed because environmental conditions impact your results.

It’s easy to overlook, but the truth is: the performance of e-coat line is directly tied to the stability of its surroundings. A small shift in temperature or a rise in humidity can cause costly problems. That’s why understanding how these fluctuations affect your coating process is crucial for maintaining consistent, high-quality results.

The Science Behind E-Coat Line Stability

Temperature and humidity are more than just numbers on a thermometer or a hygrometer; they’re the invisible forces that shape the success of your electrocoating process. In an e-coat line, the stability of both factors plays a crucial role in determining how smoothly everything runs. When conditions are right, your system works like a well-oiled machine, delivering perfect coatings every time. But when things go off track, the effects can be felt immediately, from adhesion issues to uneven coating finishes.

When the temperature rises or drops unexpectedly, it affects the viscosity of the coating bath. A warmer bath will make the coating thinner, while a colder bath may thicken it too much. These subtle changes impact the electrocoating process, making it harder to achieve consistent results. It’s like trying to paint a surface with a brush that’s either too wet or too dry — neither gives you the smooth, flawless finish you need.

Humidity is another silent disruptor. High humidity leads to moisture buildup in the system, causing condensation that can interfere with the coating’s application. When water vapor mixes with the bath, it can lead to defects like pitting, bubbles, or poor adhesion. The surface of the workpiece becomes less receptive to the coating, and what should have been a smooth, uniform layer instead becomes riddled with imperfections.

Maintaining stable environmental conditions ensures that your e-coat line operates at peak performance. By managing temperature and humidity, you can achieve the flawless coatings your business relies on and keep the process running efficiently.

Common Issues Caused by Temperature and Humidity Fluctuations

When temperature and humidity fluctuate, they don’t just change the environment — they create real, tangible problems for the e-coat line. From poor adhesion to coating defects, the effects can be devastating. Let’s take a closer look at how these fluctuations manifest in everyday production scenarios.

- Adhesion Problems

One of the most frustrating and common issues that arise from fluctuating temperature and humidity is poor adhesion. When the temperature or humidity isn’t ideal, the coating has trouble bonding properly to the substrate. This results in weak adhesion, which can lead to peeling or flaking over time. The coating may look fine initially, but as soon as the piece is subjected to stress or harsh conditions, it begins to fail. This not only affects product quality but also costs your business time and money spent on repairs and rework.

- Coating Defects

The coating itself is also vulnerable to temperature and humidity changes. High humidity can cause moisture to interact with the electrocoating, leading to defects like pitting, bubbles, or uneven finishes. These imperfections make the product look unprofessional and reduce its functionality. For example, pitting occurs when tiny pockets of air are trapped beneath the coating, while bubbles form when the moisture evaporates during the curing process. Both defects significantly impact the aesthetic and performance qualities of the coated surface.

- Increased Downtime and Maintenance Costs

Fluctuations in temperature and humidity not only affect the coating itself but also put a strain on the equipment. When the environment isn’t stable, your system is more likely to experience breakdowns, requiring more maintenance. The components of e-coat line, from the tanks to the electrical systems, can suffer from the added stress of inconsistent conditions. This leads to more downtime, which is costly and disruptive. The more you have to repair, the more it eats into your bottom line.

How Temperature and Humidity Fluctuations Affect E-Coat Line Tank Chemistry

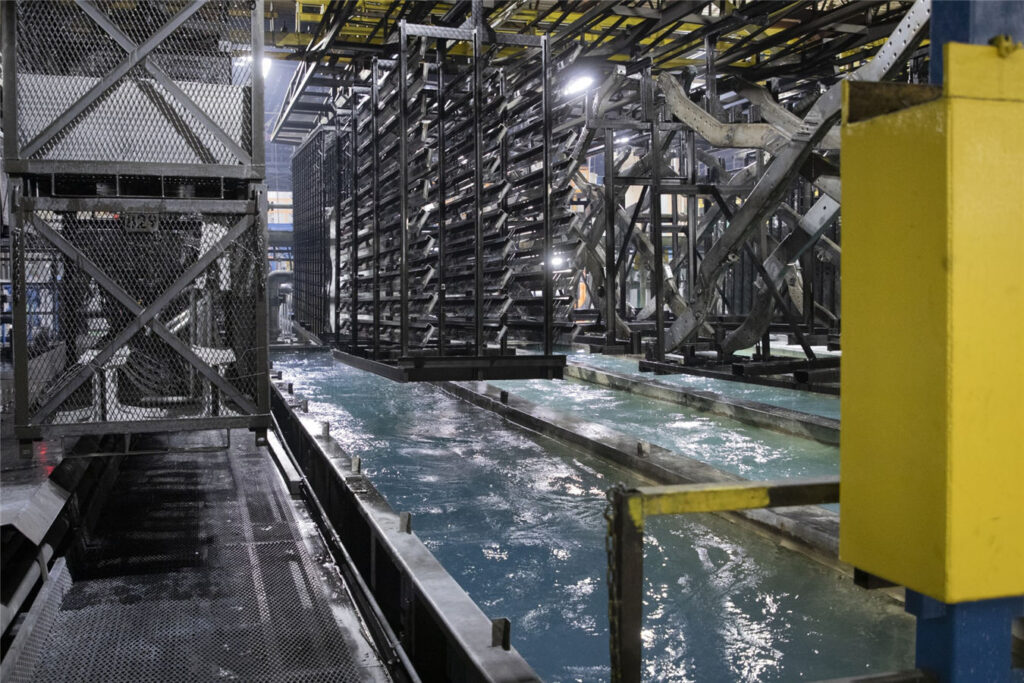

The electrocoating bath is where the magic happens — it’s the heart of e-coat line. However, this delicate system is highly sensitive to environmental changes. When temperature and humidity fluctuate, they can alter the chemistry of the bath, throwing off the balance and affecting the entire coating process. Let’s explore how these changes impact the tank’s chemistry and, ultimately, your coating quality.

- The Effect of Temperature on Electrolyte Composition

Temperature has a direct impact on the electrolyte solution in the e-coat bath. When the temperature rises, the viscosity of the bath decreases, causing the coating to become thinner and more difficult to control. On the other hand, lower temperatures increase viscosity, leading to a thicker, less even coating. Even slight shifts in temperature can affect the electrochemical process, causing uneven film thickness or adhesion issues. If the temperature fluctuates beyond the optimal range, it can even compromise the overall quality of the coating, making it prone to defects.

- Humidity’s Impact on Tank Equipment and Bath Stability

High humidity introduces another challenge — moisture. When humidity levels rise, condensation can form inside the tank and on the equipment, potentially damaging the electrical components. This moisture also interacts with the electrolyte, diluting the bath or changing its chemical properties. A diluted solution leads to inconsistent coating deposition and poor quality finishes. Additionally, the tank’s equipment can corrode due to prolonged exposure to excessive moisture, requiring costly repairs and leading to prolonged downtime.

- Interactions Between Temperature, Humidity, and Coating Thickness

The combined effect of temperature and humidity fluctuations can result in uneven coating thickness. For instance, if the temperature is too high and the humidity is also high, condensation can cause localized areas of the substrate to receive more or less coating, leading to irregular film thickness. On the other hand, low temperatures with high humidity can cause the coating to be too thin in certain areas, leading to spots with inadequate protection. These inconsistencies compromise the overall coating quality and may even lead to premature wear or corrosion of the coated product.