Why the Conveyor Chain is Contaminating the E-coat Line Bath

When you see “fish-eyes,” craters, or dark spots on your finished parts, these defects usually point to one place: a contaminated tank. While most operators check the chemistry first, they often overlook the overhead conveyor. A dirty conveyor chain acts as a constant source of pollution. It travels directly above your e-coat line tanks, dropping […]

Why is the Rectifier the “Heart” of Your E-Coat Line

Most people only notice the massive tanks and conveyor belts when they look at a professional e coat line. But the real power behind a perfect finish comes from a smaller, quieter component: the rectifier. Think of the rectifier as the engine of your entire system. It controls the electricity that pulls the paint onto […]

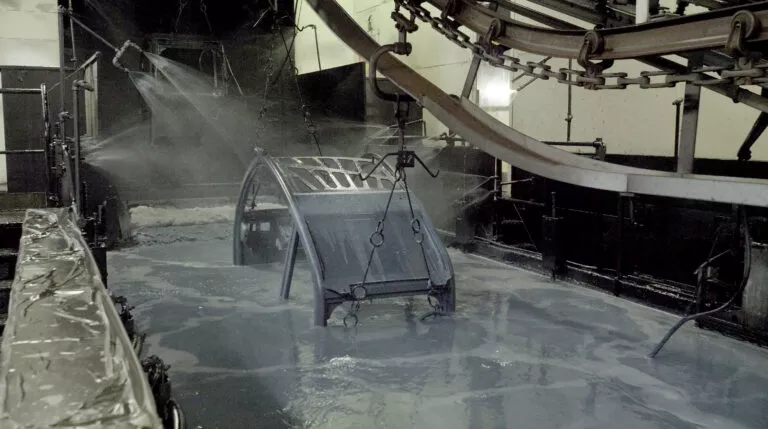

The Secret to Maintaining a Clean E Coating Line Tank

Every factory manager knows the sinking feeling of seeing “sandpaper” textures on a finished part. You check the chemicals, you test the voltage, but the culprit hides at the bottom of your tank. Sedimentation is more than just mud; it is a ticking time bomb for your e coating line. When paint particles drop out […]

The Role of Precision Filtration in Electrocoating Equipment

In the world of metal finishing, a flawless surface is the ultimate goal. You’ve likely perfected your chemistry and dialed in your voltage, but your electrocoating line still produces parts with tiny bumps or “seeds.” It’s frustrating. Often, the difference between a premium finish and a high scrap rate isn’t the paint itself—it’s the cleanliness […]

When is E-coat Line NOT the Right Choice for Your Finish

Every manufacturer dreams of a flawless, high-volume finish that lasts for decades. In that search for perfection, the e-coat line often feels like the ultimate prize. It is fast, efficient, and offers world-class corrosion protection. It’s the backbone of the automotive and appliance worlds for a reason. But here is the honest truth: an e-coat […]

Are Temperature and Humidity Variations Ruining Your E-Coat Line

In any electrocoating process, consistency is key. But temperature and humidity fluctuations can throw your e-coat line completely off balance. Seasonal changes, unexpected weather patterns, and uncontrolled indoor climates often lead to poor adhesion, coating defects, and increased downtime. Imagine the frustration when hard-earned production schedules get derailed because environmental conditions impact your results. It’s […]

The Secret to Flawless Coating: Mastering E-Coat Tank Design

When it comes to achieving flawless coating in the e-coating process, the design of the e-coat tank plays a crucial role. Every detail, from the tank’s size to its liquid flow system, affects the quality and consistency of the coating on workpieces. A well-designed e-coat tank not only ensures optimal performance but also improves production […]

Why Ultrafiltration Rinsing Is Critical After Electrocoating

In e coating line, the coating process does not truly end when the part leaves the bath. What happens immediately afterward often determines whether the final film looks smooth and uniform—or shows defects that are difficult to correct later. Residual paint solids, permeate, and conductive substances remain on the surface after electrocoating. If these materials […]

Cathodic Electrocoating Solutions for Automotive Frames and Chassis

Automotive frames and chassis are built to last, but they are also the parts most exposed to corrosion, impact, and harsh road conditions. Once rust begins inside boxed sections or welded joints, it is difficult—and often impossible—to stop. For manufacturers, this makes the choice of primer coating not just a technical decision, but a long-term […]

Why E-Coating Line Is Widely Used in Corrosion Protection

Corrosion is one of the most persistent challenges faced by industries that rely on metal parts. Whether it’s automotive components, heavy machinery, or industrial hardware, the threat of rust and degradation is ever-present. Traditional coating methods, while effective to some extent, often fail to provide long-lasting protection, especially for complex, hard-to-reach surfaces. This is where […]