When it comes to painting metal surfaces, choosing the right coating can make all the difference. E coating vs powder coating paints may seem similar at first, but they each tell a different story in terms of how they protect, beautify, and last over time. Whether it’s the sleek finish of a car part, the durable shine on a household appliance, or the rugged coating on industrial equipment, understanding these differences can help you make a smarter choice—and achieve results that truly stand out.

E Coating vs Powder Coating: Coating Principles

At the heart of the difference between e coating and powder coating is how the paint actually reaches and sticks to the surface.

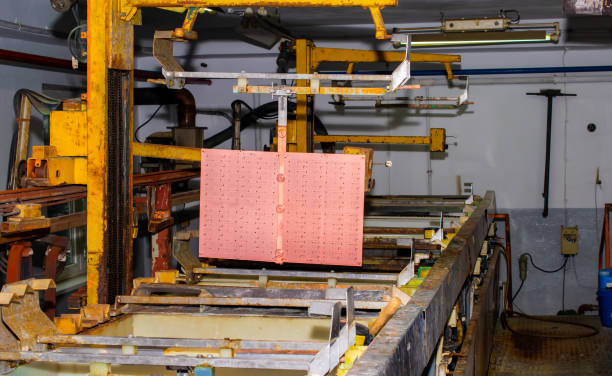

E coating paint works like a gentle magnet for paint. The metal part is dipped into a tank filled with liquid paint, and an electric field draws the paint particles evenly onto every nook and cranny. The result is a smooth, consistent coating that seems almost effortless in its perfection.

Powder coatings, on the other hand, is more hands-on. Dry powder is sprayed onto the surface, then heated to melt and fuse it into a solid layer. This process gives a thicker, durable finish that can withstand harsh conditions, but achieving perfect coverage on complex shapes may require skill and attention.

Understanding this fundamental difference helps you see why certain projects favor one paint over the other—and why knowing e coating vs powder coating is more than just a technical detail; it’s about achieving the finish you truly want.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

E Coating vs Powder Coating: Coating Uniformity

When comparing e coating vs powder coating, one of the most noticeable differences is how evenly the paint can cover a surface.

E-coat paint is a master of uniformity. The process uses an electric field to draw liquid paint particles toward the metal surface, ensuring that every contour—whether it’s a flat panel or a complex, multi-layered part—receives the same even coat. This is especially valuable in industries like automotive manufacturing, where even a tiny bare spot can lead to corrosion over time. The beauty of e coating lies in its ability to provide a finish that is smooth, consistent, and nearly flawless without extra touch-ups.

Powders also deliver strong coverage, especially on simple, open surfaces. However, achieving the same level of uniformity on intricate shapes can be more challenging. Because the powder is sprayed, sharp edges, deep recesses, or hidden angles may require extra attention from skilled operators. The good news is that, with the right equipment and technique, powder coating can still produce excellent, long-lasting results—but it demands more hands-on precision.

E Coating vs Powder Coating: Coating Thickness

The thickness of the coating is another important factor in the e coating vs powder coating discussion, and it directly affects both performance and appearance.

Electrocoating paint generally produces a thinner, more controlled layer, often in the range of 15–35 microns. This makes it ideal for parts that require tight dimensional tolerances or where multiple coating layers will be applied. The thin yet consistent film offers excellent corrosion resistance without adding unnecessary bulk, ensuring that parts still fit perfectly into assemblies.

Powder coatings, by contrast, creates a much thicker layer—typically 50–150 microns—resulting in a more rugged finish. This thickness helps protect against chips, scratches, and UV damage, making it a popular choice for outdoor structures, furniture, and heavy-use equipment. However, the added thickness can sometimes obscure fine details or require adjustments in assembly. Choosing between the two comes down to whether your priority is precision and subtlety or maximum durability and protection.

E Coating vs Powder Coating: Applications

When it comes to real-world uses, e coating vs powder coating paints serve different needs.

E-coating paint is ideal for automotive parts, appliances, and electronics—anywhere full coverage and corrosion protection are critical, even on complex shapes. While powder coatings is often chosen for outdoor furniture, railings, machinery, and construction materials, where a thicker, more durable finish can withstand weather and heavy wear.

In short, e coating is best for precise, protective layers, while powder coating shines in creating bold, resilient finishes for visible, high-use products.