Imagine a car body fresh from the assembly line or a circuit board that will power tomorrow’s technology. Before either reaches the customer, it needs more than just color—it needs a layer of protection that clings evenly to every surface, corner, and curve. This is where the e-coating line proves its value. Unlike traditional methods that may leave thin spots or miss hidden edges, e-coating works with nature’s own force—electricity—to guide paint particles into perfect balance. The result is a finish that is not only smooth to the eye, but also reliable in performance, no matter how complex the part’s shape may be.

The Core Principle of E-Coating Line: Electric Field Action

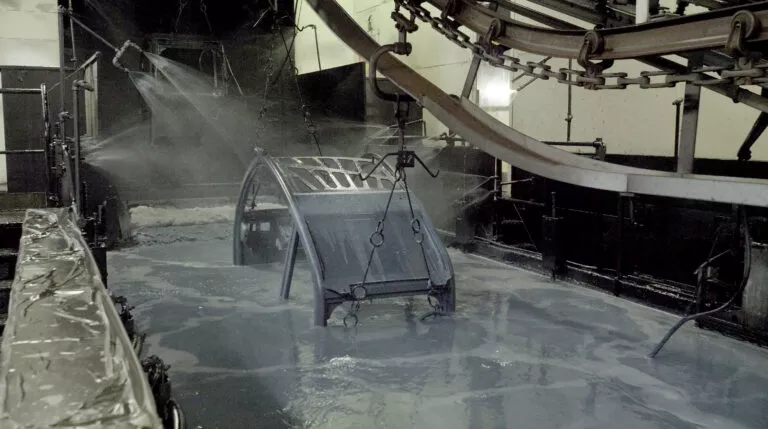

At the heart of every e-coating line is the principle of electro-deposition, where an electric field drives the coating process. When a workpiece is immersed into the e-coating tank, an electric current is applied between the part and the paint bath. This current causes the charged paint particles to migrate toward the surface of the workpiece, adhering evenly across all exposed areas.

Unlike traditional spray or dip methods, the electric field in an electrophoresis coating line ensures that coating particles are attracted with precision, covering flat panels as well as hidden corners, edges, and recesses. This electrostatic attraction makes it possible to achieve uniform coverage regardless of the part’s complexity, laying the foundation for smooth and consistent finishes.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Adhesion of Coating Particles to the Workpiece

Once the charged paint particles reach the surface, something remarkable happens—they don’t just touch the metal; they lock onto it. Guided by the electric field, each particle finds its place and clings tightly, as if the part itself is pulling the coating into a perfect embrace.

This process doesn’t discriminate between a wide flat panel or the narrow edges of a complex component. Every contour, groove, and hidden recess receives the same treatment. The result is a uniform layer of paint that feels less like it was applied on the surface and more like it became part of the part itself.

This natural attraction between the particles and the metal ensures not only even coverage but also strong adhesion, laying the foundation for a coating that will endure wear, weather, and time.

Unique Properties of E-Coating Line Paint

The success of an e-coating line is not only about the electric field—it also depends on the special characteristics of the coating material itself. Unlike ordinary paints, e-coating formulations are designed with higher viscosity and a greater solid content. This means that when particles reach the metal surface, they don’t scatter or run off; instead, they spread evenly and form a smooth, consistent layer.

Another key factor is the uniform size of the coating particles. In the tank, they remain finely dispersed, ready to respond instantly to the pull of the electric field. This balance of chemistry and physics ensures that every workpiece leaves the e-coating line with a finish that is not only visually flawless but also durable and highly resistant to corrosion.

It’s this harmony between process and material that makes e-coating stand out—transforming what could be just another layer of paint into a shield of long-lasting protection

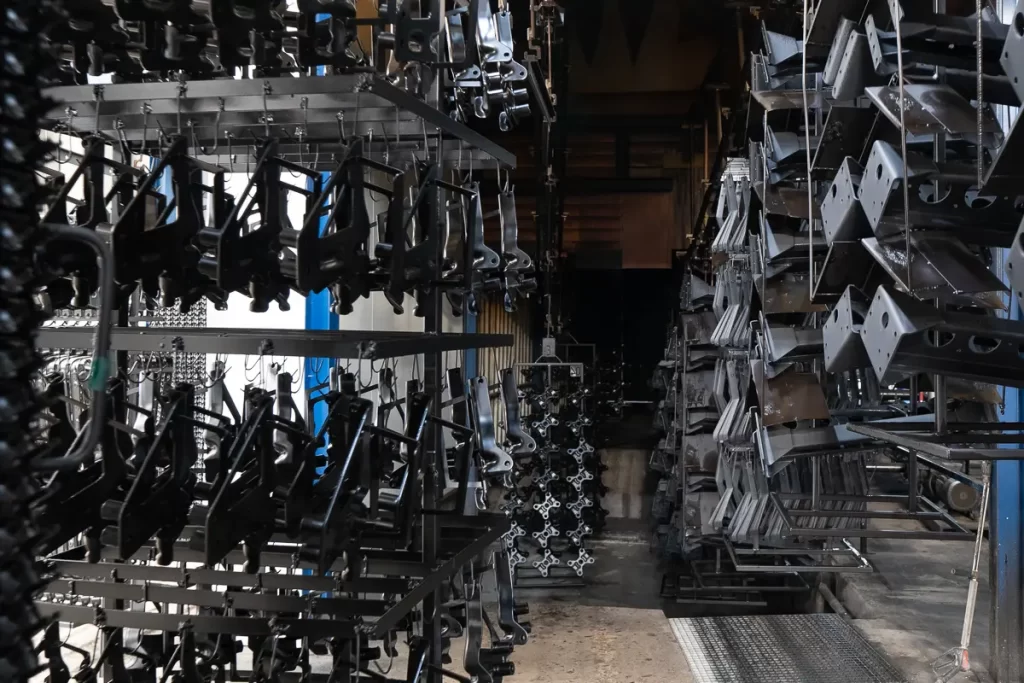

Role of Suspension and Conveyor Systems

Behind the scenes of every e-coating line, there is more than chemistry and electricity at work—there is also precision in motion. Parts don’t simply float through the process; they are carefully suspended on racks or hangers, ensuring that every surface remains fully exposed to the coating bath.

As the conveyor system slowly moves each workpiece along, it does so at a steady, controlled pace. This consistency is crucial. Too fast, and the coating may not have enough time to settle; too slow, and it may build up unevenly. The suspension and conveyor system act like a silent choreographer, guiding each part through the bath with perfect timing, ensuring that no corner is neglected.

In this way, the e-coating line becomes more than just a tank and an electric field—it becomes a fully synchronized system where movement, immersion, and coating all work in harmony to guarantee flawless results.

Precise Control of Process Parameters in the E-Coating Line

Even with the right paint and perfect suspension, the secret to a flawless finish lies in control. In an e-coating line, two variables play a decisive role: how long the part stays in the bath, and how strong the electric field is.

Think of it as fine-tuning an instrument. A short immersion may leave the layer too thin, while an extended one could build up an uneven film. Likewise, the electric field must be carefully adjusted—too weak and the particles won’t adhere properly; too strong and the coating may become overly thick. By balancing these two factors, operators ensure that every part receives just the right amount of protection.

This flexibility makes the e-coating line adaptable to a wide range of components, from small, delicate electronics to large automotive frames. Each emerges with the same promise: a uniform, durable finish ready to face years of use and exposure.