If you’re planning or upgrading an e-coat line, there’s one part of the system you really don’t want to overlook—the electrocoating conveyor. It’s not just a way to move parts from point A to point B. A good conveyor keeps everything flowing smoothly, makes sure each workpiece spends just the right amount of time in each stage, and helps your entire operation run like clockwork.

But here’s the thing—not all electrocoating conveyors are created equal. The right choice depends on your products, your layout, and how much flexibility you need. In this article, we’ll walk you through what to look for and why the right conveyor can make a big difference in the quality and efficiency of your e-coat line.

Factors to Consider When Choosing an Electrocoating Conveyor

When it comes to selecting the right electrocoating conveyor, one size definitely doesn’t fit all. The ideal system should match your production needs, plant layout, and the specific characteristics of the parts you’re coating. Here are a few key things to think about:

1. Part Size and Weight

Are you coating small brackets or large automotive frames? The size and weight of your products will directly impact the type and strength of conveyor system you’ll need. Heavy parts may require a more robust track and drive system, while smaller components need precise handling to avoid coating defects.

2. Line Speed and Throughput

How fast do you need your line to run? Your electrocoating conveyor must keep up with your desired production rate without causing bottlenecks or delays. A mismatch here can slow down your entire operation and lead to inconsistent coating quality.

3. Plant Layout and Space Limitations

Not every facility has the luxury of wide open space. Whether you’re working around columns, low ceilings, or existing equipment, your conveyor design needs to fit your real-world layout. Flexible solutions—like accumulation conveyors—are great for making the most of tight or irregular spaces.

4. Integration with Tanks, Ovens, and Other Equipment

An e-coat line is a system, and the conveyor must work in harmony with all the other parts—pretreatment, E-coat tanks, rinses, ovens, and unloading zones. Proper synchronization ensures that each part spends the right amount of time at every stage, which is essential for a high-quality finish.

5. Maintenance and Downtime

A complicated or unreliable conveyor system can become a major headache. When evaluating an electrocoating conveyor, consider how easy it is to maintain, whether replacement parts are readily available, and how quickly your team can get it back online if something goes wrong.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Benefits of Using an Accumulation Electrocoating Conveyor

Among all the conveyor options available, the accumulation electrocoating conveyor stands out—especially for manufacturers who need more flexibility, better timing control, and higher efficiency. If your production involves complex workflows or variable takt times, this type of conveyor can make a huge difference.

1. Better Flow Control

An accumulation system allows parts to pause or queue without stopping the entire line. This is especially useful when different stages—like pretreatment or curing—have different cycle times. Your line keeps running, and your operators stay in control.

2. Reduced Downtime

Because parts can accumulate temporarily, minor issues like a momentary halt in one section won’t disrupt the whole line. That means fewer complete stoppages, smoother production, and less stress for your team.

3. Increased Flexibility

Not all parts are the same. Some may need longer soak times, or slower movement through the E-coat bath. An accumulation electrocoating conveyor lets you adapt more easily to different products without redesigning the entire system.

4. Efficient Use of Space

These conveyors are great at working around tight or irregular layouts. You can “stack” work in progress without needing extra track length, which helps optimize the footprint of your coating line.

5. Safer, More Organized Workflows

By managing spacing and timing between parts, accumulation systems help prevent collisions, improve worker safety, and create a more predictable production rhythm.

Why Our Accumulation Conveyor E-coating Line Stands Out

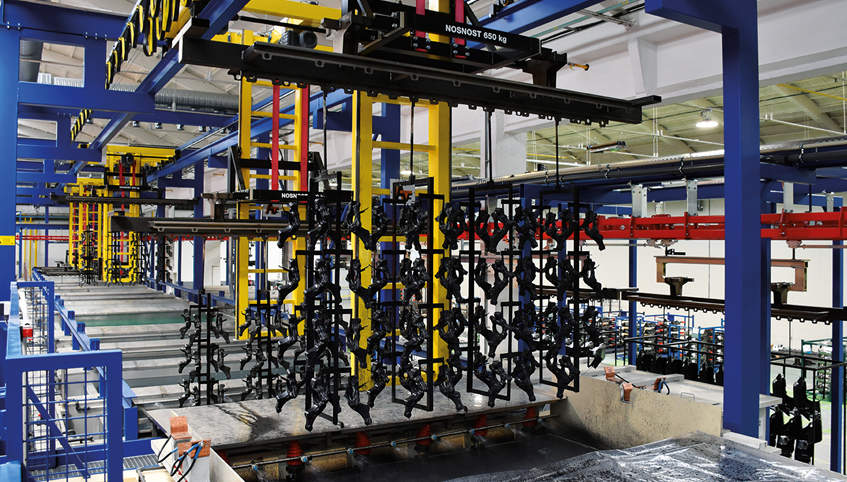

At Hinah Coating, our accumulation conveyor e-coating line is built with real-world production in mind. Whether you’re dealing with high-mix parts, tight floor space, or demanding quality standards, our solution offers the flexibility and reliability you need. Designed for seamless integration with pretreatment tanks, E-coat baths, and curing ovens, it ensures precise timing and smooth part flow at every stage. The modular structure makes it easy to maintain and expand, while heavy-duty components handle large, complex workpieces with ease. Most importantly, this system helps you reduce downtime, increase throughput, and improve coating consistency across every shift.

Conclusion

Choosing the right electrocoating conveyor isn’t just a technical decision—it’s a strategic one. The conveyor you choose will shape how your entire e-coat line performs, from productivity and efficiency to coating quality and long-term reliability. Accumulation systems offer the flexibility and control modern manufacturers need, especially in dynamic production environments.

If you’re looking for a conveyor solution that adapts to your process, minimizes downtime, and keeps your line running smoothly, it’s time to explore a smarter option. Get in touch with us today and discover how our accumulation electrocoating conveyor can take your E-coat operation to the next level.