All of us know the frustration of rework. A small imperfection on a coated part can mean hours of lost production, wasted materials, and an entire batch falling behind schedule. Rework doesn’t just cost money—it drains confidence from the process itself. When the same coating flaws keep coming back, it’s a sign that something deeper in the system isn’t under control.

That’s where modern electrocoating systems make a difference. Designed for precision and consistency, they eliminate the small errors that lead to big losses. From the first stage of pre-treatment to the final curing oven, a well-engineered electrocoating system ensures that every part leaves the line ready for assembly, not repair. Reducing rework isn’t just about saving cost—it’s about restoring trust in your production line.

Why Rework Happens in Traditional Coating Lines

Rework doesn’t happen by accident—it happens because small details are missed at critical stages. In many traditional coating lines, the process relies too much on manual adjustment and experience. When temperature, voltage, or bath balance shift even slightly, the result can be uneven film thickness, poor adhesion, or surface defects that only show up after curing.

One of the most common causes is poor pre-treatment. If oil, dust, or rust remains on the surface, the coating won’t bond properly, leading to peeling or bubbling later on. Another major factor is unstable power control during coating. Without a reliable voltage curve, the paint may deposit unevenly, leaving thin spots that require touch-up.

Bath contamination is another silent problem—tiny impurities, unfiltered particles, or imbalanced pH can ruin a whole day’s production. And even when the coating looks perfect, improper rinsing or curing can undo it all. Residue left after rinsing causes visible marks, while curing at the wrong temperature leads to soft or uneven films.

Each of these issues leads back to the same result: rework, wasted time, and frustrated operators. The key to solving them is control—consistent, automated, intelligent control at every stage. And that’s exactly what modern electrocoating systems are built to deliver.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

How Electrocoating Systems Prevent Rework at Every Stage

Modern electrocoating systems are designed to address the root causes of rework rather than simply fix defects after they appear. By controlling each step of the coating process with precision, these systems minimize errors, reduce material waste, and ensure consistent quality. The following stages show how advanced systems tackle the most common sources of rework.

- Surface Preparation: Ensuring Clean, Adhesive Surfaces

The foundation of a perfect coating begins with thorough surface preparation. Contaminants such as oil, dust, or rust can prevent proper adhesion, leading to peeling, pinholes, or bubbling. Modern electrocoating systems integrate multi-stage pre-treatment tanks, including degreasing, rinsing, and phosphating, with automated monitoring of temperature, chemical concentration, and flow rates. This ensures every part’s surface is consistently clean and chemically active. With proper surface preparation, the coating bonds evenly and securely, drastically reducing adhesion-related rework.

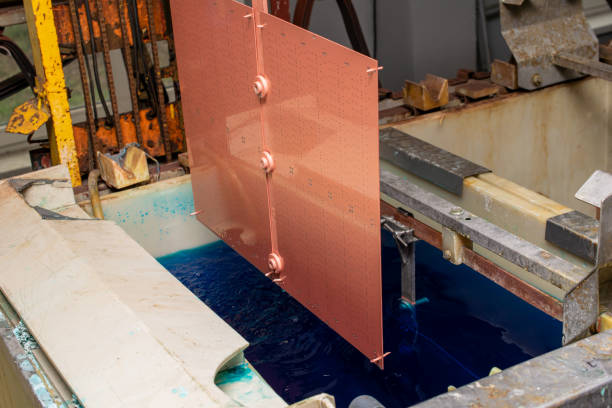

- Coating Deposition: Achieving Uniform Film Thickness

Uneven film thickness is a frequent cause of defects and rework, often resulting from unstable voltage, fluctuating current, or manual errors in traditional systems. Electrocoating systems solve this by using advanced rectifiers and precise part positioning to maintain constant voltage and current, ensuring uniform paint deposition across all surfaces, including complex shapes and edges. Real-time monitoring detects any deviations in bath conductivity or film thickness, allowing automatic adjustments. This level of precision eliminates thin spots and overcoating, reducing the need for touch-ups or rejected parts.

- Bath Management: Maintaining a Clean, Balanced Environment

A stable, contaminant-free bath is critical for consistent coating quality. Impurities, paint sludge, or incorrect pH and temperature can produce defects that may only appear after curing. Modern electrocoating systems continuously filter and ultrafilter the bath, maintaining the correct chemical balance and temperature. This ensures that each part receives the same consistent coating, preventing variations that lead to rework. By controlling the bath environment, manufacturers can rely on first-pass quality and reduce costly corrections.

- Rinsing and Neutralization: Removing Residue Before Curing

Even with perfect deposition, residual chemicals from pre-treatment or the bath can compromise coating quality. Electrocoating systems employ multi-stage rinsing to remove these residues thoroughly, often incorporating ultrafiltration to eliminate microscopic particles that might cause streaks or uneven surfaces. Clean parts entering the curing stage minimize defects such as color variation or soft spots, which are common triggers for rework. Proper rinsing ensures the coating maintains its intended appearance and durability.

- Curing: Securing the Final Finish

The final curing step locks in the coating’s durability and appearance, but improper temperature or dwell time can cause soft films, peeling, or uneven colors. Advanced electrocoating systems use precision ovens with controlled airflow and temperature monitoring, guaranteeing that every part reaches optimal curing conditions. Integrated sensors track and adjust the process in real time, ensuring consistent results across the entire production line. With controlled curing, manufacturers can trust that finished parts meet quality standards without requiring costly rework.

Conclusion

Rework is more than an inconvenience—it’s a hidden cost that quietly erodes efficiency, materials, and profit. As we’ve seen, the causes of rework span every stage of the coating process, from surface preparation to curing. Modern electrocoating systems address each of these challenges with precision, automation, and real-time control, ensuring that defects are prevented before they ever reach the production line.