In an electrophoretic coating line, the stability and purity of the coating bath determine the overall coating quality. Even the most advanced equipment cannot deliver consistent results if the bath becomes contaminated. Tiny particles, oil residues, or metal ions can quickly disrupt the chemical balance, leading to coating defects such as poor adhesion, uneven film thickness, or discoloration. Bath contamination not only increases production waste but also shortens the lifespan of the coating solution and equipment. Therefore, understanding how contamination occurs—and how to effectively control it—is essential for maintaining a stable and high-performing electrophoretic coating process.

Causes of Electrophoretic Coating Bath Contamination

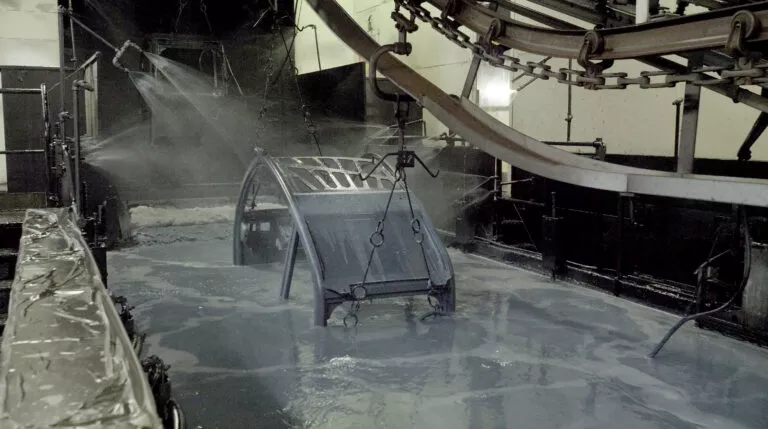

Bath contamination in an electrophoretic coating system can originate from multiple sources throughout the production process. One of the most common causes is insufficient pretreatment—when oil, dust, or metal debris remains on the workpieces before coating. These impurities are easily carried into the coating bath and can react with the paint particles, disturbing the chemical balance.

Another major contributor is metal ion contamination, often caused by the dissolution of workpiece surfaces, conveyor parts, or electrodes. When the electrical field is not properly controlled, excessive current can accelerate corrosion and release unwanted ions into the bath, which then alters conductivity and film formation behavior.

Oil and grease from conveyor chains or air systems can also find their way into the coating solution. Even trace amounts of oil can weaken coating adhesion or cause “fish eyes” on the surface. In addition, dust and microorganisms in the environment may accumulate over time, especially if filtration or ventilation systems are poorly maintained.

Finally, inadequate filtration and circulation accelerate contamination buildup. Without proper removal of suspended solids, sediments and foreign particles gradually reduce bath clarity and stability. Once the contamination level exceeds the control range, the electrophoretic coating line may suffer from uneven current distribution, leading to coating defects and reduced efficiency.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Methods for Detecting and Monitoring Bath Contamination

Effective bath management in an electrophoretic coating system relies on accurate and consistent monitoring. Detecting contamination early allows operators to take corrective action before it affects coating performance or product quality. There are several reliable methods to identify and track bath contamination in modern electrophoretic coating lines.

One of the most fundamental indicators is conductivity measurement. Since electrophoretic coating depends on a stable electrical field, any fluctuation in bath conductivity can signal contamination by metal ions or chemical imbalance. A sudden increase may indicate corrosion or dissolved metals, while a drop often suggests dilution or material loss.

Regular pH testing is another essential practice. The pH value directly affects the charge and mobility of coating particles. Contaminants such as oils, cleaning agents, or reaction byproducts can shift the pH outside its optimal range, leading to poor deposition and inconsistent film thickness. Maintaining a stable pH ensures uniform electrochemical performance throughout the bath.

Monitoring the solid content of the coating bath also provides critical insight into contamination levels. A decline in solids typically means excessive drag-out or poor recovery, while abnormal increases could point to impurities or dirt entering the system. Periodic sampling and analysis of solid concentration help keep the coating properties stable.

Visual inspection remains an invaluable, low-cost method. Discoloration, turbidity, or sediment at the bottom of the tank are clear signs of contamination buildup. Advanced automated electrophoretic coating lines often incorporate real-time sensors and filtration control systems, allowing continuous tracking of bath parameters and automatic alerts when conditions deviate from preset limits.

Preventive Measures to Maintain a Clean E-Coating Bath

Preventing bath contamination in an electrophoretic coating line is always more effective and economical than correcting it after it occurs. Consistent control and disciplined maintenance practices are key to sustaining a clean and stable coating environment.

The first and most critical step is ensuring proper pretreatment and rinsing. Any residual oil, grease, or dust left on workpieces before coating can easily be carried into the bath. High-quality degreasing, phosphating, and thorough rinsing are essential to prevent impurities from entering the electrophoretic coating system. Regularly replacing rinse water and monitoring its conductivity further minimizes cross-contamination.

Efficient filtration and circulation systems also play a vital role. Continuous filtration removes suspended solids and prevents sediment buildup, while proper circulation ensures even temperature and chemical distribution. Incorporating ultrafiltration (UF) units allows for the separation of unwanted ions and contaminants from the coating bath, extending bath life and maintaining stable coating performance.

Routine equipment cleaning and maintenance should never be overlooked. Electrodes, tanks, and piping systems should be inspected regularly to remove accumulated deposits or corrosion. Even minor dirt or rust on the anode or cathode can disrupt electrical balance and introduce metal ions into the bath.

By combining these preventive measures, you can significantly reduce contamination risks, ensure consistent coating quality, and extend the service life of both the coating bath and the electrophoretic coating equipment.