Walk into any factory running an electrophoretic painting line, and you’ll hear the steady hum of pumps, the rhythmic movement of conveyors, and the quiet confidence of a process built for precision. Everything seems perfectly balanced—until you look closer. Somewhere in the tanks, in the rinse water, or at the filters, small amounts of paint are being lost every single minute. It’s invisible at first, but over weeks and months, that waste becomes measurable—cutting into profits, raising costs, and leaving behind an unnecessary environmental footprint.

Reducing paint waste in electrophoretic painting isn’t just a technical adjustment—it’s a commitment to smarter, cleaner manufacturing. It’s about understanding the journey of every paint particle, guiding it exactly where it needs to go, and giving none of it away to inefficiency. When every drop is used with purpose, production becomes not only more economical but also more sustainable—a reflection of true process mastery.

Understanding Paint Utilization in Electrophoretic Painting

In an ideal electrophoretic painting line, every particle of paint should have a purpose — traveling through the bath, attaching perfectly to the metal surface, and forming a smooth, even coating. But in reality, things are never that perfect. Paint is lost through drag-out, overflow, or unstable bath conditions, often quietly and unnoticed. Over time, these small inefficiencies grow into real waste, reducing profitability and consistency.

To understand paint utilization, you need to look beyond the tank and into the rhythm of the process. The concentration of solids, the flow rate, the voltage, and even the geometry of each part — all of these affect how efficiently paint particles are deposited. A bath that is slightly off balance can cause particles to drift, settle, or remain suspended, instead of bonding to the surface as intended.

The key is awareness. Operators who understand the behavior of their electrophoretic painting system can see patterns others might miss — subtle changes in current, the way the bath “breathes,” or how the rinse water looks at the end of a shift. Paint utilization isn’t just a number on a report; it’s a reflection of how harmoniously your process is running. When the system is tuned just right, efficiency follows naturally — and every drop of paint fulfills its purpose.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Controlling Bath Composition for Efficient Electrophoretic Painting

The heart of every electrophoretic painting system lies in its bath. It’s where chemistry meets precision — a delicate balance of paint solids, water, voltage, and temperature working together to create a flawless coating. When that balance shifts, even slightly, the entire process begins to lose its rhythm. Too high a concentration can lead to uneven coating thickness, while too low reduces paint transfer efficiency. The result? More waste, more rework, and less consistency.

Maintaining the right bath composition is less about strict formulas and more about awareness. The pH, conductivity, and solids content must be watched like the pulse of the process. Small deviations often go unnoticed until quality issues appear, and by then, paint has already been lost. This is where automatic monitoring and control systems become invaluable — continuously measuring, adjusting, and restoring the bath to its optimal state before problems have a chance to grow.

Another key to reducing waste is ultrafiltration. This technology recovers valuable paint particles from rinse water or overflow, sending them back into the bath instead of down the drain. It’s a quiet yet powerful way to improve efficiency — recycling what would otherwise be lost. Over time, this not only saves material but also keeps the bath cleaner, the coating more stable, and the process more sustainable.

A well-balanced bath is like a calm heartbeat in an electrophoretic painting line — steady, predictable, and efficient. The more precisely it’s maintained, the less paint you lose and the more confidence you gain in every part that comes out of the tank.

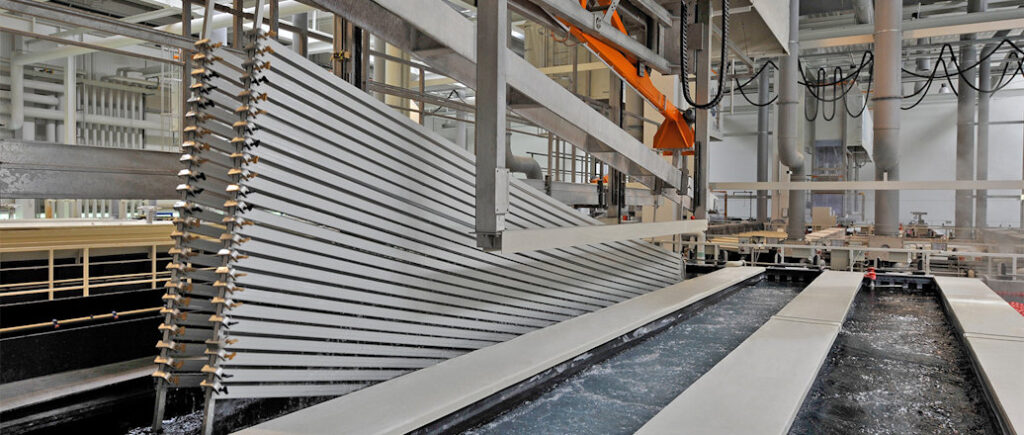

Optimizing Rinsing Stages in Electrophoretic Painting Line

After parts leave the electrophoretic painting tank, they carry more than just a perfect coat — a thin film of paint solution still clings to their surface. If that excess isn’t managed properly, it becomes one of the biggest hidden sources of paint waste in the entire process. Each droplet that drips away or washes down the drain is material that could have been reused, profit that could have been saved.

This is where the rinsing stages come in — the unsung heroes of paint recovery. A well-designed electrophoretic painting line doesn’t treat rinsing as an afterthought; it treats it as a crucial step of material efficiency. Multi-stage rinsing, especially when arranged in a counterflow or reverse cascade pattern, allows paint particles from the first rinse to move backward toward the tank instead of being lost. It’s a simple idea with enormous impact: let clean water flow in one direction and valuable paint flow in the other, meeting in the middle at just the right balance.

Paint recovery systems can push this even further. By using ultrafiltration or return pumps, much of the paint collected during rinsing can be sent back into the bath, maintaining concentration and reducing chemical consumption. Over time, these systems not only save paint but also stabilize the bath composition, leading to more consistent coating thickness and smoother finishes.

When rinsing is optimized, the electrophoretic painting process becomes a closed loop — efficient, sustainable, and almost self-sustaining. Nothing is wasted; everything has a place. It’s a small but powerful shift in mindset that turns rinsing from a routine task into a quiet act of precision and respect for the material itself.

E-Coating Equipment Maintenance and Filtration

In any electrophoretic painting system, clean and well-maintained equipment is the quiet foundation of efficiency. When filters clog or residue builds up, paint circulation becomes uneven and waste begins to grow unnoticed. Regular cleaning, timely filter replacement, and proper circulation checks keep the bath stable and the coating consistent. Modern filtration systems further enhance this by recovering usable paint and removing impurities before they cause trouble. A well-maintained line doesn’t just run better — it uses every drop of paint with purpose, turning routine care into one of the simplest, most effective ways to reduce waste.