A poorly designed e-coating line rarely fails overnight. Instead, it drains money slowly—through longer cycle times, unpredictable film build, rising rejection rates, and maintenance that never seems to end. At first, these issues feel like “normal production problems,” but over time they reveal a deeper truth: the line’s design was never built to support stable, long-term performance. Many manufacturers don’t notice the real cost until the losses have already become part of their daily routine. We will take you beneath the surface to show how those hidden costs form, and why a strong design matters far more than most people expect.

The Operational Inefficiency Built Into a Weak E-Coating Line

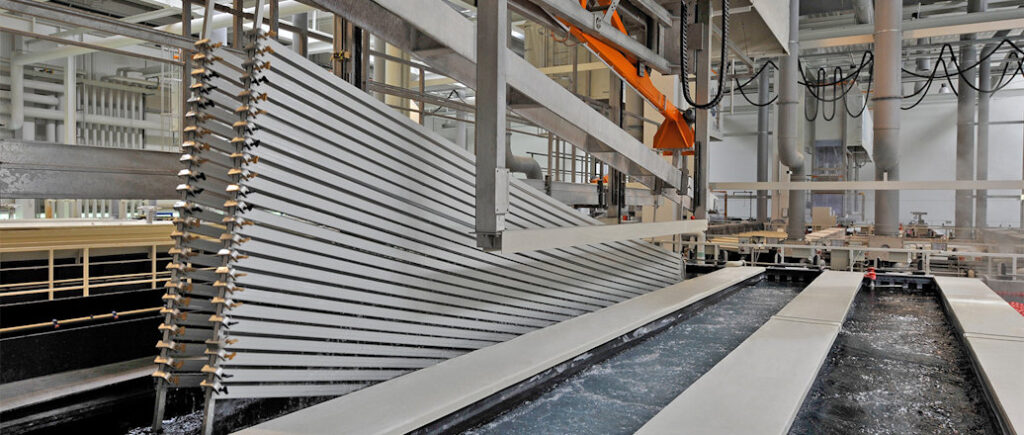

Even when production seems to run “normally,” a weakly designed e-coating line quietly adds extra cost to every shift. It might start with something as small as poor tank circulation or an imbalanced pre-treatment layout, but those details shape everything that follows. When the chemistry isn’t flowing the way it should, the line consumes more energy, drags down bath stability, and forces operators to compensate with constant adjustments.

Over time, these inefficiencies slow the entire rhythm of the workshop. Cycle times stretch longer than planned, parts wait in queues, and throughput quietly slips below what the line was meant to handle. Operators spend more time checking, correcting, and manually guiding the process—tasks that shouldn’t be necessary in a well-built system. None of these problems appear dramatic on their own, but added together, they turn into a steady stream of waste that eats into daily production margins.

Quality Problems That Don’t Show Up Until It’s Too Late

When an e-coating line is poorly designed, quality issues rarely scream for attention at the start—they accumulate quietly. A tank that’s just a bit too shallow, a poorly positioned anode, or an unstable electrical setup might not seem serious at first. Yet these details decide whether a part receives a smooth, even film or a patchy coating that fails under real-world conditions.

The signs emerge gradually. One batch comes out with thin coverage on edges, the next shows inconsistent film build, and sooner or later the rejection pile grows higher than anyone wants to admit. What makes this worse is the unpredictability—operators can’t trace the problem to a single cause because the flaw is built into the line itself. The result is a constant cycle of rework, extra labor, and customer claims that could have been avoided with a stable, well-balanced design.

The Maintenance Burden of a Flawed E-Coating Line

A poorly designed e-coating line doesn’t just produce inconsistent quality—it demands constant attention. Pumps positioned in tight corners, filters that are hard to access, or circulation lines arranged without long-term maintenance in mind all become daily frustrations. Operators spend more time fixing issues than running the line, and every shutdown, even the short ones, disrupts the entire production rhythm.

The real cost isn’t just the replacement parts or the technician hours—it’s the unpredictability. A line that stops unexpectedly forces work-in-progress delays, interrupts curing schedules, and throws delivery timelines off balance. When breakdowns happen often enough, the team begins to treat them as “normal,” even though they’re quietly draining profit from every production cycle.

What should be simple, preventive maintenance turns into emergency troubleshooting. Components wear out faster than expected, service visits become routine, and the line never truly reaches a stable, reliable state.

Conclusion

The true cost of an e-coating line is never just the number on the purchase contract—it’s the daily losses hidden in slow cycles, inconsistent coating quality, and constant maintenance interruptions. When the design isn’t solid from the start, these problems become part of the production routine, quietly consuming time, labor, and customer trust.

A well-designed e-coating line does the opposite: it runs predictably, protects quality, and keeps maintenance simple. It gives manufacturers stability—the kind that turns every shift into reliable output instead of a series of small battles. For any company looking to upgrade or evaluate its current system, the most valuable step is to look beyond the surface and measure the design by its long-term cost, not just its upfront price.