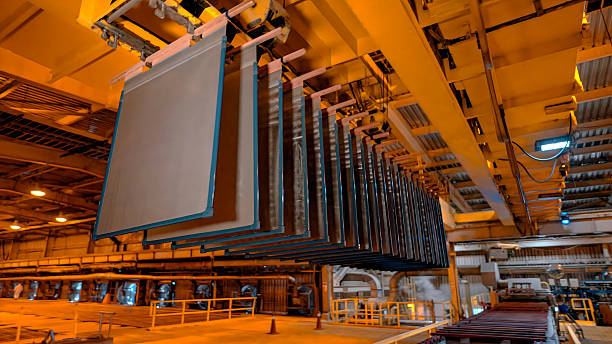

Upgrading an existing electrocoating line is never just about replacing hardware — especially when the conveyor system is involved. As the silent backbone of the entire E-coat process, the conveyor links every stage from pretreatment to curing, and even a small change can ripple through the whole line. Many manufacturers plan retrofits to improve efficiency or adapt to new part designs, only to encounter issues such as misalignment, grounding problems, or unexpected downtime. Understanding these potential challenges in advance can help ensure your upgraded electrocoating conveyor system runs smoothly, supports consistent coating quality, and delivers the performance your production line truly needs.

Assessing Existing Line Before Installing New Electrocoating Conveyor

Before introducing a new electrocoating conveyor into an existing line, it’s important to take a step back and fully understand the condition and layout of what you already have. Many retrofit problems start not with the new equipment, but with small issues that have built up over years of use — worn chains, uneven supports, or outdated drive systems that can’t maintain stable speed control.

Begin by mapping your current conveyor path, including elevation changes, load points, and transfer areas. Check how these align with the tanks, ovens, and work zones in your line. Even slight misalignment can cause drag-out, poor coating coverage, or unbalanced load distribution once the new conveyor is in place. Also review whether the existing hangers and carriers can properly support part weight and maintain good electrical contact, since grounding consistency directly affects coating thickness.

Finally, evaluate whether upgrading makes more sense than a complete replacement. For some systems, reusing an old track or drive mechanism can save cost but limit performance improvements. A careful assessment helps ensure that the new electrocoating conveyor fits both your production layout and long-term goals, minimizing surprises once installation begins.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Design and Performance Criteria for Efficient Electrocoating Conveyor

Once the condition of your existing line is clear, the next step is to define what the new electrocoating conveyor needs to achieve. Every design decision — from conveyor speed to material choice — directly impacts coating quality, production rhythm, and maintenance stability.

The first factor to consider is speed control and dwell time. Electrocoating requires precise immersion and withdrawal speeds to maintain consistent film thickness. If the conveyor moves too quickly through the bath, coverage can become uneven; too slowly, and energy consumption and drag-out increase. Selecting a drive system with smooth variable speed control ensures each part spends the right amount of time in every stage of the process.

Material selection also plays a crucial role. Because the electrocoating environment is humid and chemically active, conveyor frames, chains, and hangers should be resistant to corrosion and easy to clean. Stainless steel, coated components, or modular plastic rollers are common solutions that extend system life and reduce unplanned downtime.

Finally, pay attention to part handling and grounding. The conveyor design must allow for stable part positioning and secure electrical contact between the hanger and the part. Even a slight loss of contact can cause poor coating deposition or uneven current distribution. When designed properly, an electrocoating conveyor not only moves parts efficiently — it becomes an integral part of achieving a uniform, high-quality finish.

Integrating the Electrocoating Conveyor with Process and Control Systems

An upgraded electrocoating conveyor must work in harmony with every stage of the coating process — not just fit the layout. The conveyor’s speed, movement, and timing need to synchronize with pretreatment tanks, rinse sections, the E-coat bath, and curing ovens to keep parts moving smoothly without idle time or congestion. Proper grounding between the conveyor and workpieces is equally vital, as unstable contact can cause patchy coating or voltage fluctuations. Integration also extends to automation: sensors that monitor chain tension, line speed, or part tracking can help detect problems early and reduce downtime. A thoughtful integration plan ensures the conveyor doesn’t operate as a standalone system but as a fully connected component of your electrocoating line, supporting both process stability and long-term reliability.

Planning, Maintenance, and Long-Term Reliability

Successful conveyor upgrades rely as much on planning and maintenance as on design. Before installation, schedule the retrofit around production cycles to minimize downtime, and ensure spare parts, alignment tools, and technical support are ready in advance. After the new electrocoating conveyor is running, preventive maintenance becomes essential — regular inspections of chains, drives, and grounding points can prevent unexpected stops and coating defects. Over time, maintaining consistent lubrication, tension, and alignment will extend the conveyor’s life and preserve coating quality. It’s also worth planning for flexibility: a system designed with easy access and modular components can adapt to future product changes or automation upgrades, ensuring the electrocoating conveyor remains reliable and efficient for years to come.