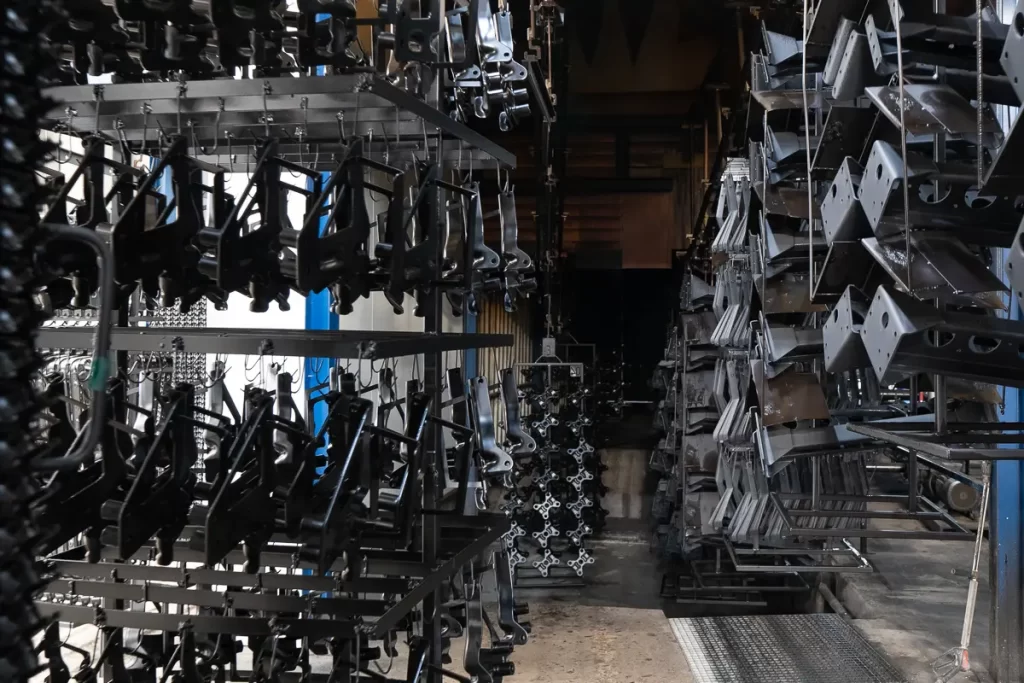

Metal is everywhere around us—shaping the cars we drive, the appliances we use every day, and the structures that hold our cities together. Yet no matter how strong it looks, bare metal has one unforgiving enemy: corrosion. A single scratch, a hidden corner left unprotected, or months of exposure to moisture can quietly eat away at its strength. Traditional coatings help, but they often fall short in the places we can’t see or reach. This is where an electrophoresis coating line changes the story. Instead of relying on chance coverage or multiple coats, it uses the power of electricity to pull paint particles directly onto every part of the surface—even the edges, recesses, and hidden welds. The result is not just another layer of paint, but a true shield: thin, uniform, and remarkably tough.

What Makes Electrophoresis Coating Line Unique

At the heart of an electrophoresis coating line is a deceptively simple idea: let electricity do the work of perfect coating. The process begins with paint particles dispersed in water, each carrying an electric charge. When a metal part is immersed in this bath and a current is applied, those charged particles are drawn toward the surface like iron filings to a magnet.

But the brilliance lies in what happens next. Instead of just sticking to the outermost face, the coating forms evenly across every contour of the metal. It doesn’t matter if it’s a flat panel, a sharp corner, or a hidden cavity—the electric field pulls the coating into places where spray guns and brushes can never reach. Even weld seams and recessed areas that typically remain vulnerable receive the same protective layer as the most visible surfaces.

This mechanism is more than just efficient; it’s transformative. It ensures that the coating is not only uniform but also tightly bonded to the substrate. The result is a surface prepared for long-term defense—consistent, complete, and reliable in a way traditional methods simply can’t match.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Why Electrophoresis Coating Redefines Corrosion Resistance

Corrosion is the silent enemy of metal. It doesn’t announce itself with drama—it creeps in through tiny scratches, exposed edges, or hidden corners, gradually weakening the structure until failure becomes inevitable. Traditional spray or dip coatings can help, but they often leave gaps in coverage, especially on complex shapes or recessed areas. Even a thin uncoated spot can be enough to start the rusting process.

1. Complete Coverage of Every Surface

This is where an electrophoresis coating line truly changes the game. By using an electric field to deposit charged paint particles, the process guarantees that every nook and cranny of the metal is coated. Sharp corners, inner cavities, and weld seams—which are often the first points of corrosion—receive the same consistent protection as the most visible surfaces. The coating is uniform, dense, and free of the pinholes or thin spots that can compromise durability.

2. Dense, Durable, and Chemically Resistant Film

The chemical properties of electrophoretic paint further enhance its defensive power. Once cured, the film forms a tight, cross-linked network that acts as a barrier against water, oxygen, and corrosive salts. In salt spray tests—a standard measure of corrosion resistance—electrophoresis-coated parts consistently outperform traditional coatings, often lasting several times longer before the first signs of corrosion appear.

3. Proven Longevity in Real-World Conditions

Durability isn’t the only advantage. The strong adhesion of the electrophoretic layer means it stays bonded even under mechanical stress, bending, or minor impacts. Scratches are less likely to expose the underlying metal, and the metal’s structural integrity remains intact for far longer than with conventional finishes.

In practical terms, this means that industries relying on metal components can count on their products to withstand harsh environments without constant maintenance or premature failure. The electrophoresis coating line doesn’t just apply paint; it creates a protective armor that’s uniform, reliable, and built to last. It is this combination of complete coverage, chemical resistance, and adhesion strength that truly redefines what it means to protect metal.

Conclusion

An electrophoresis coating line is more than just a finishing process—it is a fundamental shift in how we protect metal. By ensuring complete coverage, forming a dense and chemically resistant film, and delivering long-lasting durability, it addresses the weaknesses that have long plagued traditional coatings. Beyond the technical advantages, its efficiency and consistency make it a practical solution for industries that demand both performance and reliability. In every hidden corner, every sharp edge, and every exposed surface, the electrophoresis coating line stands as a silent guardian, redefining what true metal protection means.