When a perfect, mirror-smooth electrocoating finish suddenly turns rough or uneven, most engineers look to the paint bath, pretreatment, or temperature control for answers. Yet, the real culprit often lies in a place few people suspect — the ecoat power supply.

This unassuming device quietly drives every stage of the coating process, controlling the electric current that determines how paint particles deposit on your parts. When it’s unstable, underpowered, or poorly configured, even the best coating materials can’t save you from defects. The result? Blotchy finishes, thin spots, and endless rework.

Understanding how your ecoat power supply influences coating quality isn’t just a matter of troubleshooting — it’s the key to achieving consistent, flawless finishes and maximizing production efficiency.

How Unstable E-Coat Power Supply Affects Coating

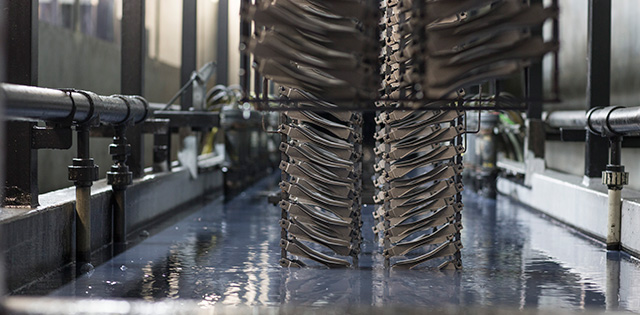

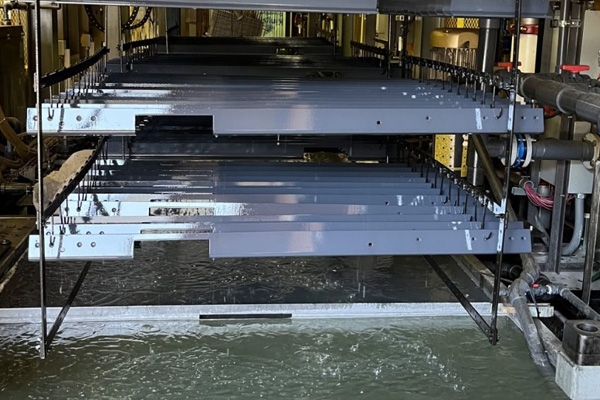

An ecoat power supply isn’t just a power source — it’s the heartbeat of the entire electrocoating process. When that heartbeat falters, the results show immediately on your finished parts. Voltage fluctuations or irregular current flow can change how paint particles migrate and deposit, leading to visible coating defects that no amount of polishing can fix.

An unstable ecoat power supply often causes uneven film thickness across different areas of the workpiece. Corners and edges may appear under-coated, while flat surfaces become overly thick, wasting material and energy. Even small deviations in current density can disrupt the chemical balance inside the bath, producing rough textures or dull finishes instead of the smooth, glossy surface you expect.

The impact goes beyond aesthetics. Electrical instability also affects coating adhesion and corrosion resistance. When the current isn’t steady, the paint layer may fail to fully crosslink, leaving micro-voids that shorten the coating’s lifespan. Over time, this translates into rework, quality complaints, and higher operating costs — all because of a neglected ecoat power supply.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

Common E-Coat Power Supply Problems

In most electrocoating lines, defects rarely appear out of nowhere — they build up quietly as the ecoat power supply begins to drift from its ideal performance. Understanding the common problems behind this can save hours of troubleshooting and prevent costly production losses.

- Voltage fluctuation

When the output voltage of the ecoat power supply fluctuates, the deposition rate of paint particles becomes unstable. You’ll start noticing inconsistent coating thickness — sometimes too thin on edges, sometimes too thick in recesses. Over time, these variations cause uneven curing and reduce the overall durability of the coating.

- Insufficient rectifier capacity

If your ecoat power supply isn’t powerful enough to maintain steady current for large or complex parts, it struggles to keep voltage consistent throughout the bath. The result is incomplete coverage and patchy surfaces, especially on components with deep cavities or irregular shapes.

- Poor grounding or unstable wiring

Even a perfectly designed ecoat power supply can fail if the electrical connections around it are weak. Loose cables, poor grounding, or corroded terminals increase resistance, which means the voltage reaching the part is lower than expected. This leads to thin or spotty coating areas that are often mistaken for bath chemistry problems.

- Aging or damaged components

Over time, rectifiers, transformers, and diodes inside the ecoat power supply can wear out. These deteriorations cause intermittent current drops or unstable output that’s hard to detect until coating defects start appearing. Regular inspection and preventive maintenance are crucial to keeping performance stable.

How to Prevent Defects with the Right Power Supply Setup

Preventing coating defects begins with maintaining a stable and well-matched ecoat power supply. The key is to ensure your system can deliver consistent voltage and current under all production conditions. Choosing a digital-controlled rectifier, upgrading outdated components, and installing real-time monitoring systems can significantly improve coating uniformity and energy efficiency. Regular maintenance—checking wiring, grounding, and cooling systems—helps sustain stable output and extend the power supply’s lifespan. When your ecoat power supply runs smoothly, so does your entire coating line, producing clean, durable, and defect-free finishes every time.