When it comes to achieving a flawless electrophoretic coating, most focus on voltage, bath chemistry, or curing temperature. But there’s another, often-overlooked factor quietly affecting every part you coat — contamination inside the electrophoretic coating tank.

Even the smallest impurity — a trace of oil, metal dust, or chemical residue — can compromise the integrity of your coating. What begins as a barely visible particle can lead to fish eyes, rough surfaces, or poor adhesion across an entire batch of components. Over time, these invisible contaminants can reduce efficiency, drive up maintenance costs. Keeping your electrophoretic coating tank clean isn’t just about routine maintenance; it’s about protecting the heart of your coating system.

Major Sources of E-Coat Tank Contamination

Contamination rarely happens overnight. It builds up slowly, hidden within the daily rhythm of production — until one day, the quality of your electrophoretic coating begins to decline without an obvious reason. Understanding where these impurities come from is the first step to keeping your system clean and stable.

- Poor Pretreatment or Rinsing Stages

When parts are not properly degreased or rinsed, traces of oil, dust, or pretreatment chemicals travel straight into the electrophoretic coating tank. These residues not only disturb the chemical balance but also create surface defects that no amount of post-curing can fix.

- Inadequate Filtration Systems

Every tank relies on filtration to keep contaminants under control. But when filters are clogged, undersized, or rarely replaced, suspended particles start to circulate within the bath. Over time, these impurities accumulate and directly affect coating thickness and appearance.

- Cross-Contamination Between Baths

In multi-stage coating lines, the boundaries between cleaning, rinsing, and coating are crucial. If these zones are not properly isolated, materials from earlier stages can seep into the coating bath — carrying unwanted ions, oils, or debris that alter the tank chemistry.

- Environmental Factors

Airborne dust, humidity, and poor water quality are silent contributors to tank contamination. Even microscopic impurities in the process water can destabilize the electrophoretic coating process, causing subtle but persistent quality fluctuations.

- Human Error and Negligence

Finally, one of the most common sources of contamination is human error. A skipped maintenance schedule, mishandled chemical addition, or unclean tools can all introduce new contaminants into an otherwise balanced system. Consistency in practice is just as important as precision in technology.

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

How Contamination Affects Electrophoretic Coating Performance

When contamination begins to build up inside an electrophoretic coating tank, the impact on quality is both subtle and far-reaching. At first, the signs may seem insignificant — a few uneven finishes, a slight loss of gloss — but over time, these small irregularities grow into major performance problems. Impurities such as oil, dust, or metal particles interfere with the delicate balance of the coating bath, disrupting the electrical field that drives the deposition process.

The result is often a surface full of imperfections: pinholes, rough textures, or visible craters that no amount of curing can fix. Beyond appearance, contamination can also cause uneven film thickness, especially on complex parts where the electric field is harder to control. These inconsistencies weaken corrosion resistance and reduce the long-term durability of the coated product.

As the contamination worsens, the bath’s conductivity changes, forcing the system to work harder to maintain coating uniformity. Energy consumption rises, filters clog faster, and operators spend more time on maintenance and troubleshooting. Eventually, this silent decline leads to higher production costs, lower efficiency, and a growing number of rejected parts.

In the end, contamination in an electrophoretic coating line is more than just a maintenance issue—it’s a threat to quality, efficiency, and reputation. Preventing it requires not only technical precision but also a disciplined approach to daily operations.

Preventive Measures for a Clean Electrophoretic Coating Tank

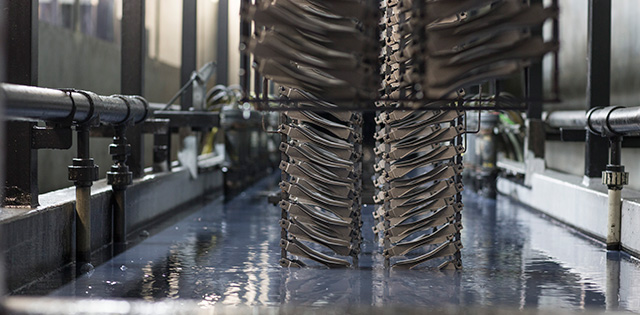

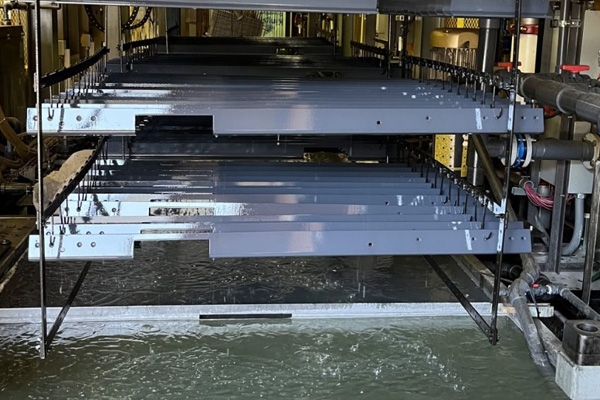

- Maintain Reliable Filtration and Circulation

A well-designed filtration system is the first line of defense against contamination in an electrophoretic coating tank. Continuous filtration removes suspended particles, while proper circulation ensures chemicals remain evenly mixed and prevents sediment from settling at the bottom. Filters should be inspected and replaced regularly to maintain consistent performance.

- Ensure Proper Pretreatment

Parts entering the coating tank must be thoroughly degreased and rinsed to avoid carrying oils, dust, or residues into the electrophoretic coating line. Using clean water and maintaining correct pH levels in each pretreatment stage are critical to keeping the bath chemistry balanced and the coating quality consistent.

- Regular Bath Monitoring

Frequent testing of key parameters such as pH, conductivity, and solids content allows operators to detect early signs of contamination or chemical imbalance. Timely adjustments help prevent small issues from turning into major production problems.

- Schedule Routine Cleaning and Maintenance

Routine cleaning of tanks, anodes, and circulation pipes removes sludge and buildup that can compromise coating efficiency. Establishing a strict maintenance schedule ensures the electrophoretic coating tank remains in optimal condition, reducing downtime and defects.