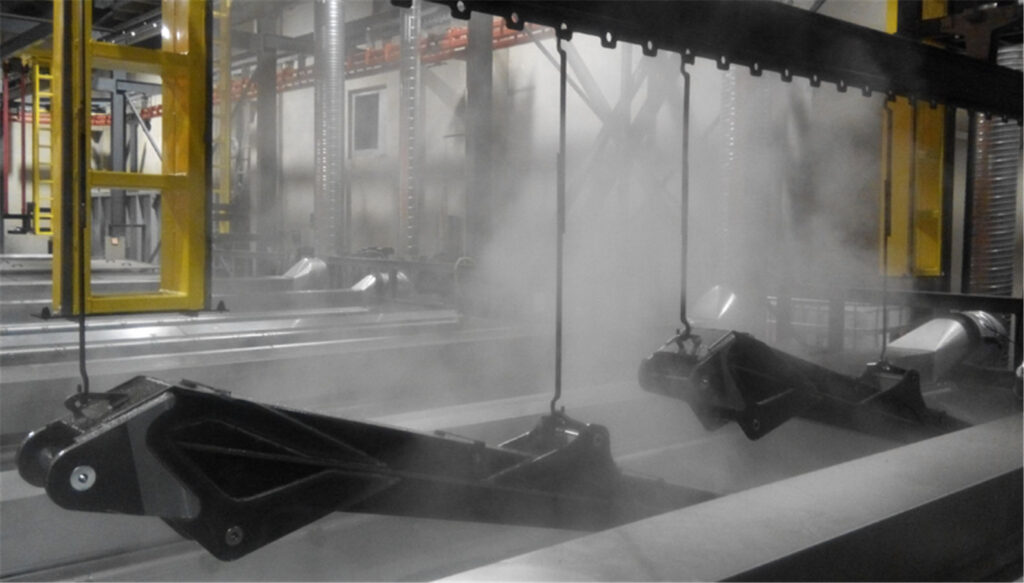

The e-coating tank is the heart of your e-coating line, where the critical electrochemical deposition process occurs. Its proper design, operation, and maintenance directly determine coating quality, production efficiency, and operational costs. Neglecting tank care risks defects, unplanned downtime, and costly repairs. This guide outlines essential best practices to optimize your e-coating line’s performance, prevent sedimentation and contamination, extend equipment life, and ensure consistent, high-quality coatings—keeping your entire e-coating line running smoothly and profitably.

I. E-Coating Tank Design Fundamentals for the E-Coating Line

1.1 Tank Types: Batch vs. Continuous Lines

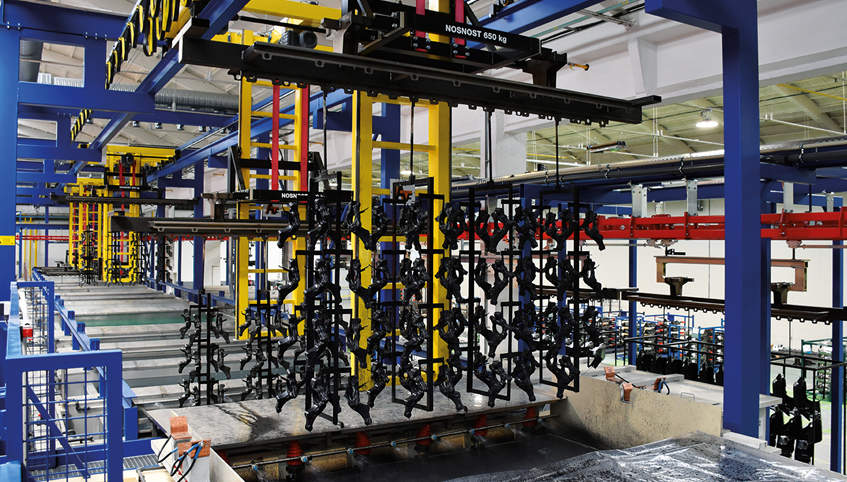

Square tanks suit batch processing, while ship-shaped tanks are engineered for conveyorized continuous e-coating lines, optimizing workflow efficiency.

1.2 Construction & Materials

Tanks require 8–10 mm low-carbon steel with double-sided welding for structural integrity. Internally, fiberglass-reinforced plastic (FRP) lining provides corrosion resistance (2-year typical lifespan).

1.3 Critical Design Dimensions

Maintain 300–400 mm between parts and anode membranes. Ensure ≥400 mm bottom clearance to prevent collisions and ≥300 mm liquid depth above parts for uniform coating. Tank length must match conveyor speed and immersion time.

1.4 Entry & Exit Optimization

A 30° entry angle minimizes air pockets. Slope the tank bottom toward drains for efficient maintenance drainage. Install adjustable exit weirs to control flow and direct foam to overflow tanks (volume = 10% main tank). Safety features include:

- 200–300 mm tank rim height above liquid level

- ≥50 mm overflow pipes to storage tanks

- 60–80 mesh non-conductive screens (FRP/coated stainless steel) between tanks

- Magnetic rods for metal contaminant removal

Let's Have A Chat

Get An E-coating Line Planning !

Match Your Products, Get The Solution & Price..

II. Operational Best Practices for Your E-Coating Line Tank

2.1 Pre-Operation Checks

Before starting your e-coating line, verify tank grounding integrity and inspect all welds/pipes for leaks. Damaged FRP linings must be repaired immediately to prevent corrosion and electrical hazards. Always conduct a 15–20 kV pressure test post-repair.

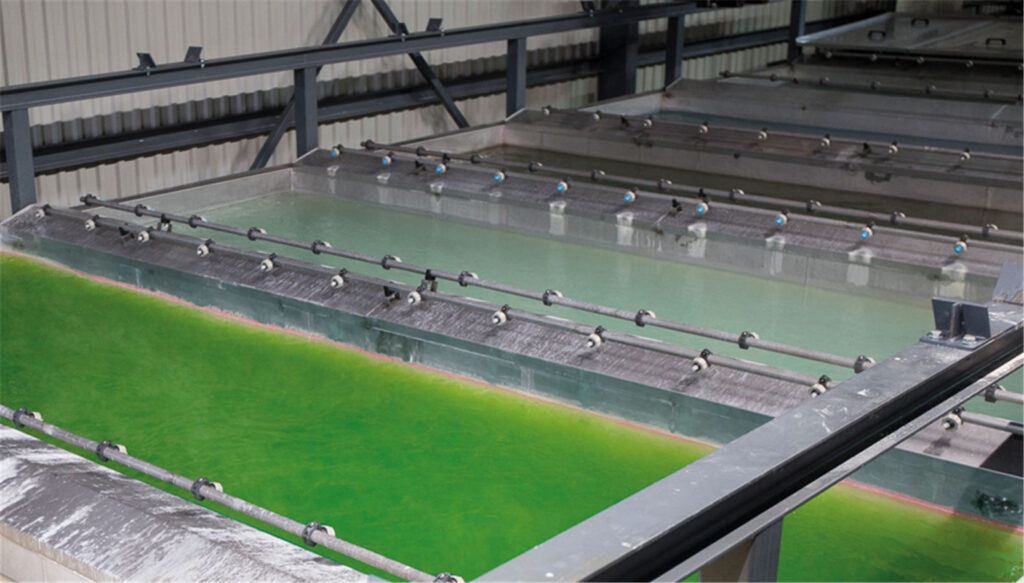

2.2 Maintaining Bath Parameters

Consistently monitor critical bath parameters: temperature (affects film thickness), pH (impacts adhesion), solids content, and conductivity. Optimize surface flow using the adjustable exit weir to sweep foam and contaminants toward the overflow tank (maintained at 10% main tank volume).

2.3 Avoiding Dead Zones & Sedimentation

Ensure agitators run continuously to prevent paint settling. Confirm the tank bottom slopes toward drains for complete fluid evacuation during maintenance. Eliminate flat corners where sediment accumulates.

Pro Tip: Regularly clean 60–80 mesh overflow screens and magnetic rods to capture metal debris (e.g., weld slag).

III. Essential Maintenance for Your E-Coating Line’s Lifespan

- Daily/Weekly Cleaning Routines

Regularly wipe tank edges and surrounding areas using approved diluents and deionized water. Prevent contaminants from entering the bath by ensuring no cleaning residue splashes into the tank. Inspect overflow screens (60–80 mesh) for blockages – clogged filters reduce flow to the overflow tank (maintained at 10% main tank volume) and compromise contamination control.

- Filtration & Contaminant Management

Clean or replace non-conductive screens (FRP or coated stainless steel) between the main and overflow tanks monthly. Integrate magnetic rods downstream of screens to capture ferrous debris like weld slag or grinding dust. Verify overflow pipes (≥50 mm diameter) remain clear and securely connected to storage tanks for spill recovery.

- Structural Integrity & Safety Upkeep

Monitor the FRP tank lining for damage – typical lifespan is 2 years. Repair cracks immediately by draining the tank and applying certified epoxy coatings. After repairs, conduct a 15–20 kV pressure test to validate insulation integrity. Ensure the tank rim always sits 200–300 mm above normal fluid levels as a safety buffer.

- Drainage & Sediment Prevention

During scheduled maintenance, fully drain the tank using sloped-bottom drain points. Remove settled solids from corners to eliminate dead zones. Inspect agitator nozzles for paint buildup, which reduces flow velocity and encourages sedimentation.

IV. Conclusion

Consistent, proactive care of your e-coating tank is the cornerstone of a high-performing e-coating line. By implementing the design principles, operational checks, and maintenance protocols outlined here, you directly combat downtime, extend equipment lifespan by years, and ensure flawless coating quality batch after batch. Treating your tank not as a passive vessel but as the dynamic heart of your process unlocks significant cost savings through reduced waste, energy efficiency, and minimized emergency repairs. Transform these best practices into standard operating procedures—your e-coating line’s reliability and profitability depend on it. For expert audits or custom maintenance solutions, contact Hinah to optimize your e-coating operation today